AI and machine learning’s potential to drive greater visibility, control, and insight across shop floors while monitoring machines and processes in real-time continue to attract venture capital. $62 billion is now invested in 5,396 startups concentrating on the intersection of AI, machine learning, manufacturing, and Industry 4.0, according to Crunchbase.

PwC’s broader tech sector analysis shows a 30% year-over-year growth in funding rounds that reached $293.2 billion in 2021. Smart manufacturing startups are financed by seed rounds at 52%, followed by early-stage venture funding at 33%. The median last funding amount was $1.6 million, with the average being $9.93 million.

Abundant AI startup opportunities in smart manufacturing and industry 4.0

According to Gartner, “The underlying concept of Industry 4.0 is to connect embedded systems and smart production facilities to generate a digital convergence between industry, business, and internal functions and processes.” As a result, Industry 4.0 is predicted to grow from $84.59 billion in 2020 to $334.18 billion by 2028. AI and machine learning adoption in manufacturing are growing in five core fields: smart production, products and services improvements, business operations and management, supply chain, and business model decision-making. Deloitte’s survey on AI adoption in manufacturing found that 93% of companies believe AI will be a key technology to drive growth and innovation.

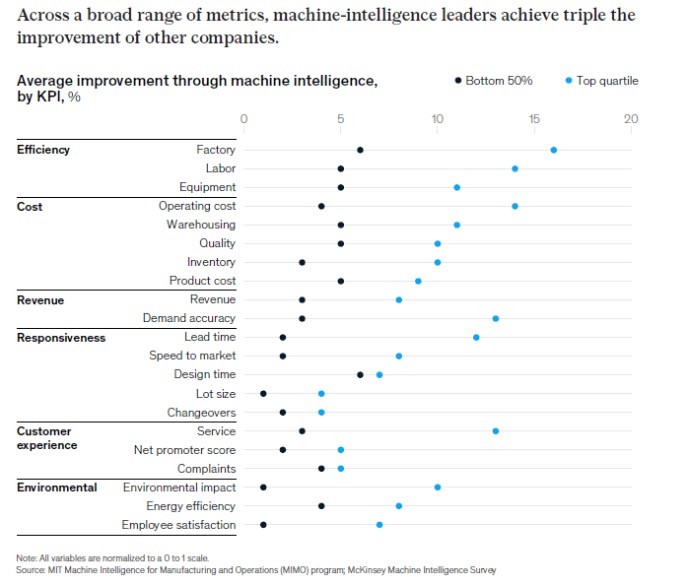

Machine intelligence (MI) is one of the primary catalysts driving increased venture capital investment in smart manufacturing. Startup CEOs and their customers want AI and machine learning models based on actual data, and machine intelligence is helping to make that happen. An article by McKinsey & Company provides valuable insights into market gaps for new ventures. McKinsey’s compelling data point is that those leading companies using MI achieve 3X to 4X the impact of their peers. However, 92% of leaders also have a process to track incomplete or inaccurate data – which is another market gap startups need to fill.

McKinsey and the Massachusetts Institute of Technology (MIT) collaborated on a survey to identify machine intelligence leaders’ KPI gains relative to their peers. They found that leaders achieve efficiency, cost, revenue, service, and time-to-market advantages. Source: Toward smart production: Machine intelligence in business operations, McKinsey & Company. February 1, 2022.

Based on the uplift MI creates for new smart manufacturing startup funding and the pervasive need manufacturers have to improve visibility & control across shop floors, startups have many potential opportunities. The following are five that AI and machine learning is helping to create:

- AI-enabled Configure, Price, and Quote (CPQ) systems that can factor in supply chain volatility on product costs are needed. Several startups are already using AI and machine learning in CPQ workflows, and they compete with the largest enterprise software providers in the industry, including Salesforce, SAP, Microsoft, and others. However, no one has taken on the challenge of using AI to factor in how supply chain volatility changes standard and actual costs in real-time. For example, knowing the impact of pricing changes based on an allocation, how does that impact standard costs per unit on each order? Right now, an analyst needs to spend time doing that. AI and machine learning could take on that task so analysts could get to the larger, more complex, and costly supply chain problems impacting CPQ close rates and revenue.

- Using AI-enabled real-time data capture techniques to identify anomalies in throughput as an indicator of machine health. The aggregated data manufacturing operations produced every day holds clues regarding each machine’s health on the shop floor. Automated data capture can identify scrap rates, yield rates and track actual costs. However, none of them can analyze the slight variations in process flow product outputs to warn of possible machine or supply chain issues. Each process manufacturing machine runs at its cadence or speed, and having an AI-based sensor system track and analyze why speeds are off could save thousands of dollars in maintenance costs and keep the line running. In addition, adding insight and intelligence to the machine’s real-time data feeds frees quality engineers to concentrate on more complex problems.

- Industrial Internet of Things (IIoT) and edge computing data can be used for fine-tuning finite scheduling in real-time. Finite scheduling is part of the broader manufacturing systems organizations rely on to optimize shop floor schedules, machinery, and staff scheduling. It can be either manually intensive or automated to provide operators with valuable insights. A potential smart manufacturing opportunity is a finite scheduler that relies on AI and machine learning to keep schedules on track and make trade-offs to ensure resources are used efficiently. Finite schedulers also need greater accuracy in factoring in frequent changes to delivery dates. AI and machine learning could drive greater on-time delivery performance when integrated across all the shop floors a manufacturer relies on.

- Automated visual inspections and quality analysis to improve yield rates and reduce scrap. Using visual sensors to capture data in real-time and then analyze them for anomalies is in its nascent stages of deployment and growth. However, this is an area where captured data sets can provide machine learning algorithms with enough accuracy to identify potential quality problems on products before they leave the factory. Convolutional neural networks are an effective machine learning technique for identifying patterns and anomalies in images. They’re perfect for the use case of streamlining visual inspection and in-line quality checks in discrete, batch, and process manufacturing.

- Coordinated robotics (Cobots) to handle assemble-to-order product assembly. The latest cobots can be programmed to stay in sync with each other and perform pick, pack, ship, and place materials in warehouses. What’s needed are advanced cobots that can handle simple product assembly at a more competitive cost as manufacturers continue to face chronic labor shortages and often run a shift with less than half the teams they need.

Talent remains an area of need

Manufacturers’ CEOs and COOs say that recruiting and retaining enough talent to run all the production shifts they need is the most persistent issue. In addition, those manufacturers located in remote regions of the world are turning to robotics to fulfill orders, which opens up opportunities for integrating AI and machine learning to enable cobots to complete assemble-to-order tasks. The unknown impact of how fast supply chain conditions change needs work from startups, too, especially in tracking actual cost performance. These are just a few opportunities for startups looking to apply AI and machine learnings’ innate strengths to solve complex supply chain, manufacturing, quality management, and compliance challenges.

By Louis Columbus